Working Group | Process safety – A drill-down into Management of Change

Event description

Process safety – Management of change (MoC)

What is Management of Change (MoC)?

A Management of Change (MOC) policy is a type of standard operating procedure that allows management teams to address company-wide changes in a structured way.

MOC provides a safe and systematic approach to managing changes in your organisation. These changes can include updating equipment, training a new workforce, opening new facilities, or updating maintenance procedures.

Having a MOC policy in place can help ensure a smooth and safe transition from an existing process to a new efficient way of doing things.

Benefits of MoC

Change can be challenging for any business. 70% of complex, large-scale organisational change programs don’t reach their stated goals.

In addition, when you have multiple people, facilities, machines, and environmental factors, it can be challenging to ensure all employees are equally informed about necessary changes.

A well-structured Management of Change system benefits the entire organization as well as individuals. MOC provides visibility across different departments and work functions, encouraging cross-functional teams to work together on shared goals.

Ultimately, this leads to better and safer implementation of new equipment, policies, or practices.

In this Working group, we will discuss topics including:

- How effective is your MoC process?

- What is your policy on Management of Change?

- How do you manage ‘ever-growing’ action lists?

- How do you classify the level of change?

- How effective is your governance committee?

- What systems are you using?

- How do you communicate the changes?

- What is the coverage of your MoC process (e.g. electrical, process, IT, Org Structure, Administrative)?

- How do you manage MoC across these areas (e.g. centralised, federated per discipline)?

About the host:

SEQ Water, Mt Crosby West Bank

Get Directions

The Mt Crosby West Bank Water Treatment Plant (WTP) turns raw water into safe, drinkable water for the Brisbane and Ipswich area.

Two water treatment plants are located at Mt Crosby – East Bank and West Bank. Combined, the plants can produce up to 1000 megalitres of drinking water per day.

All water treated must adhere to the stringent Australian Drinking Water Quality Guidelines. The basic water treatment processes include coagulation, flocculation, sedimentation, filtration and lastly, disinfection of water.

For most of us in the Greater Brisbane and Ipswich areas, every time we drink a glass of water from the tap, it is likely that the water came from this facility.

Mt Crosby Water Treatment Plant Fact Sheet

Agenda:

08:30 - Arrival and introductions

08:45 - Topic overview – Management of Change

09:00 - Presentation

10:00 - Morning tea

10:30 - Facilitated discussions

12:00 - Lunch

12:45 - Site tour of West Bank and East Bank Water treatment plants

2:30 - Event Close

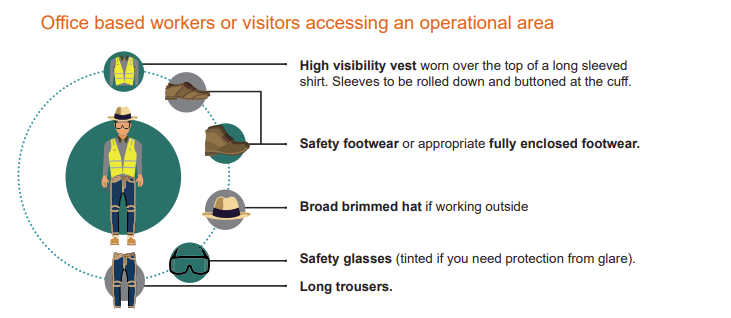

PPE Requirements:

- Long sleeve shirts – (hi-vis if possible)

- Long pants

- Fully enclosed flat shoes

- Hat (wide-brimmed)

- Water bottle

- Seqwater will provide hi-vis vests and safety glasses

Who should attend?

This event is ideal for Assets, Maintenance, Engineering, Reliability and Change managers.

This event is open to IPA members only.

As a member of IPA you can register up to 2 people, subject to availability, to attend this event.

When do I need to register by?

Registrations close 7 days before the event.

Registrations are based on a "first come, first served" basis.

There are no allocated seats with membership.

Who can I contact for further information?

Samantha Jeffrey | National Engagement & Events Manager

samantha@industrypartners.com.au

0438 058 823

Please note that we may take photos/videos at IPA events for use in marketing or social media. If you wish to be exempted from these, please contact the event organiser.

Tickets for good, not greed Humanitix dedicates 100% of profits from booking fees to charity