Vic Jesús Sifonte | Melbourne 3 Day | Reliability Centered Maintenance RCM-R | July 2023| SIRF ISW

Event description

MELBOURNE 3 Days - Face to Face

NOTE: Day 3 includes certification on the RCM-R process

COURSE OUTLINE:

- Know the scope and benefits of RCM applied according to the SAE JA1011 Standard.

- Understand the requirements of a genuine RCM process.

- Understand the role of the methodology within the context of Physical Asset Management.

- Practice the process steps with assets from your plant.

- Select failure management policies

- Distinguish the attributes of the process.

- Know the steps and requirements for the effective implementation of the process in your organization.

- Establish the bases for the certification of RCM-R® analysts, facilitators and instructors.

- Selection of Failure Consequences Management Policies

- Combination of interactive training & hands on activities.

Course content includes:

- Asset Management

- History of RCM and its Relevance in Today's Industry

- The RCM-R® Process

- Preamble to the process

- Functions and Failures

- Symptoms and Causes of Failures

- Failure Impact Assessment

- Summary of Failure Consequences Management Strategies

- Selection of Failure Consequences Management Policies

- Implementation of the process

LEARNING OUTCOMES:

Learn the Fundamentals of RCM-R®: Gain a solid understanding of the core principles, concepts, and terminology of Jesus Sifonte's RCM-R® approach, which builds upon traditional RCM methodologies with innovative enhancements for today's complex industries.

Understand Risk Management Integration: Learn how to seamlessly integrate risk management into your RCM process, enabling you to develop maintenance strategies that consider both the probability and consequences of failure, leading to more proactive and effective risk mitigation efforts.

Learn Advanced Failure Prediction Techniques: Develop the skills to apply advanced analytical techniques to identify and assess failure modes with greater accuracy. This increased precision will help you create targeted maintenance strategies that enhance asset reliability and performance.

Optimize and Prioritize Maintenance Tasks: Acquire the knowledge to effectively prioritize maintenance tasks based on their impact on asset reliability and overall risk. This risk-based prioritization ensures the efficient allocation of resources and reduces downtime and maintenance costs.

Implement Continuous Improvement Strategies: Learn how to foster a culture of continuous improvement within your organization, driving consistent evaluation and optimization of your maintenance strategies. This focus on ongoing enhancement ensures your organization stays ahead of emerging challenges and maintains a competitive edge.

Tailor RCM-R® to Your Organization's Needs: Gain the ability to customize the RCM-R® framework to your specific industry, organization, and assets. This adaptability allows you to scale RCM-R® to deliver maximum value and effectiveness, regardless of the size or complexity of your organization.

Measure and Communicate RCM-R® Success: Develop the skills to measure the success of your RCM-R® implementation and effectively communicate its value to key stakeholders within your organization. This understanding will help you showcase the benefits and drive support for ongoing RCM-R® initiatives.

BUSINESS BENEFITS:

- Know the scope and benefits of RCM applied according to the SAE JA1011 Standard.

- Understand the role of the methodology within the context of Physical Asset Management.

- Asset Management

- History of RCM and its Relevance in Today's Industry

- The RCM-R® Process

- Preamble to the process

- Functions and Failures

- Symptoms and Causes of Failures

- Failure Impact Assessment

- Summary of Failure Consequences Management Strategies

- Selection of Failure Consequences Management Policies

- Implementation of the process

Jesús Sifonte RCM-R® Brochure

ABOUT JESÚS SIFONTE:

Thought leader, Conference speaker, consultant, instructor and coach on asset reliability and maintenance. Creator of RCM-R®, an optimized approach of the original RCM methodology, and co-author of the Publication Reliability Centered Maintenance - Reengineered (RCM-R®): Practical Optimization of the RCM Process with RCM-R®. Jesús holds a Bachelor Degree in Mechanical Engineering from the University of Puerto Rico, a Master of Maintenance and Reliability Engineering Degree from Monash University in Australia and, ASNT level 3A Vibration Analyst, among other professional credentials.

Jesús is Co-Founder of Conscious Reliability and president of PdMtech, a service and consulting firm founded in 2001 with operations in Canada and Puerto Rico. Mr. Sifonte also collaborates with IMMP (Mexico), CMMI (Latin America and Spain) and Conscious Asset (Canada) as Master Instructor and Consultant. He is an active member of PEMAC Asset Management Association of Canada and collaborates as Vice President of the Greater Toronto Area Chapter. He is also an Examiner for the International Reliability Centered Maintenance Certification Committee.

His book, presents a vastly updated approach to the traditional reliability centered maintenance (RCM) methodology. It focuses on optimizing the RCM process, incorporating risk management, and providing practical strategies for implementing RCM in various industries. Jesús Sifonte's work has been widely recognized for its contribution to the field of reliability engineering and maintenance management

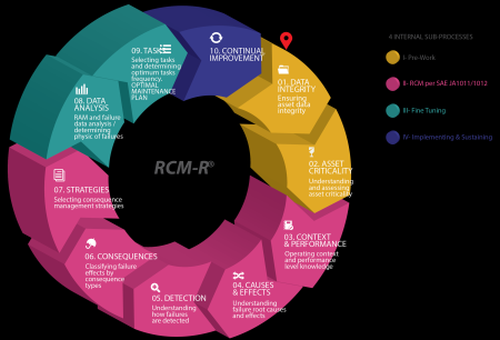

RCM-R® is an optimized process for the formulation of policies for managing the consequences of failures in assets and processes, which consists of five pillars:

- Data Integrity

- RCM according to SAE JA1011

- RAM analysis

- Weibull analysis

- Continuous improvement.

RCM-R® CYCLE OVERVIEW

TESTIMONIALS:

I enjoyed learning the logical structure of the RCM process. The thought processes involved will be beneficial to my work. Performance Engineer from Power Generation Industrie, Trinidad and Tobago

The Tools were leaned in the RCM course and applied in real situations to prevent premature issues. Senior Maintenance Strategy Officer from Public Transportation Industry, Canada

The class was very well-paced. The instructor was very knowledgeable about multiple areas and could answer all questions. Reliability Engineer from Bio-Pharma Sector, USA

What I liked the most was studying the development of the RCM-R exercise from its initial context to its final stage. This will help us identify in a more effective way the equipment we want to optimize through this strategy. Reliability Engineer from Oil Industry, Middle East

I liked that even though the subject matter was out of my expertise; the instructor took time to make it clear. Maintenance Specialist from Pharmaceutical Industry, USA

The mastery of the subject by the instructor is impressive; we are filled with enthusiasm for the project we are about to start. Planning Engineer from Distilled Spirits - Alcoholic Beverage Industry, Canada

The best, s in doubt are the practical workshops that are carried out as you advance in the learning of the theory. Lead Mechanical Engineer from LNG Industry, Nigeria

I realized that sometimes we are blind during the maintenance we do on a day-to-day basis and there are better methods to apply them in the different processes. I will continue with the advanced course. Maintenance Supervisor from Aviation Industry, India

WHAT COMES WITH THE COURSE?

Each participant will receive a pdf copy of Jesús Sifonte's latest "Course Manual"

WHO SHOULD ATTEND?

The workshop serves as a foundation for professionals wishing to become proficient in the application of reliability-centered maintenance. It is also ideal for professionals looking to start their career in reliability and want to get an overview of the tool.

FAQs: WHEN DO I NEED TO REGISTER BY?

Bookings will close 1 week before the event unless sold out

WHO CAN I CONTACT FOR FURTHER INFORMATION?

info@sirfrt.com

Jeff Naylor +6 1409 535 239

Please contact us for group discounts.

Tickets for good, not greed Humanitix dedicates 100% of profits from booking fees to charity